The sentiment among many property developers is that waterproofing is expensive and unnecessary. However, costly corrective measures become a painful lesson for many. Due to its relative porosity, concrete can allow water and other chemicals to seep into it. Left unattended, it can lead to the deterioration of a building.

Wet soil under a foundation can swell or lose strength. This is one of the reasons why foundation is always dry. It’s worth remembering that getting it right the first time is key, as coming back to fix it is an expensive affair.

Look for construction leads

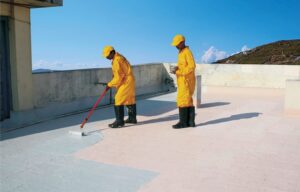

It is therefore advisable that the concrete be waterproofed. However, choosing the best way to waterproof concrete has continued to be a daunting task for most developers. By ensuring that the passage of water through a concrete is prevented and that hydrostatic pressure is resisted, a concrete can be waterproofed from the positive side (outside), the negative side (inside) or from the inside of the concrete itself. even (integral systems).

In most cases, the most widely used positive side technology is sheet membrane sealing. This has deterred most entrepreneurs from adopting it. Beal a manufacturer of waterproofing products developed Mortex 25 years ago, a mineral mortar that combines aesthetics that includes different shades, colors, finishes; and technical characteristics which include: thin thickness, wear resistance, flexibility and adhesiveness.

The cost

According to John Gichohi, Operations Manager at Kenya Waterproofing Company, most contractors seek to remove waterproofing to save costs. Some have also chosen to believe in the idea that waterproofing cannot be relied upon. “ “To waterproof a floor, for example, will require the entire area to be excavated and the work to be redone,” adds Gichohi.

Additionally, Mr. Mustafa Jawadwala from Build Basic Chemicals India says it is important to have a bit of technical knowledge and trust in the product you are buying in order to be sure you are paying for what you are buying. get.

Bituminous membranes

Due to the high cost of waterproofing a flat roof house, people avoid such house designs, while in developed countries like America, flat roof houses are quite common. For such roofs, the APP membrane, a bitumen-based waterproofing solution can work very well. But their high cost usually deters potential buyers from buying them.

According to Caitlin O’Riley of Derbigum manufacturer of reinforced waterproofing membranes in South Africa, when applying bituminous membranes, surfaces should be smooth, clean and free of protrusions. All substrates must be fully cured and there can be no excessive moisture content in the screeds. The area should be properly primed and all turns should be a minimum of 100mm wide and properly sealed to each other. Particular attention should also be paid to counter flashings, expansion joints and thresholds.

We have developed these hot melt bituminous membranes in our laboratory in Alrode South Johannesburg specifically to be better suited to the harsh African sun, whilst retaining robust low temperature flexibility. The highest quality APP modified bitumen is coated around high strength fiberglass reinforcements, giving the products dimensional stability once applied and a proven service life of over 20 years,” said Ms O’Riley

Mr. Régis Fouere from Icopal one of the largest manufacturers of flat and pitched roofing and waterproofing solutions across Europe recalls that in addition to being durable, bituminous membranes offer excellent tensile strength while maintaining critical flexibility.

Kilimanjaro International Airport

Although waterproofing materials are normally expensive, according to Pedro Carvalho of EFFISUS a supplier of integrated solutions for waterproofing, waterproofing, thermal and acoustic insulation in Portugal; if you buy fully integrated systems with good technical support, the long-term benefits are worth it.

Effisus Ecotoit

Reversing leaks is always expensive and time consuming and it is advisable to deal with the problem early on. Effisus has carried out projects in African countries such as Angola.

Furthermore, RENOLIT has delivered waterproof roofs all over the continent: from the LGV station in Casablanca to the Telecom industrial buildings in Mauritius, passing through the National Assembly of Benin, to name but a few.

In addition to this, RENOLIT has also delivered waterproofing membranes for civil engineering projects such as tunnels in North Africa, drinking water deposits in West Africa or floating covers in Central Africa”, Climent added.

Alkormsart favorable to areas of strong solar radiation

According to Tommy Nachman Business Development Manager of Haogenplast Ltd , a company that manufactures PVC waterproof membranes for various applications, market leader in the development and manufacture of technical and decorative coatings and membranes formulated for extreme UV conditions, floating covers for water tanks constitute a new technological advance which, if well adopted, will take the construction industry a step further from the current situation.

Another emerging trend that is a fast growing segment of the commercial roofing market according to TremcoMatt Recko, director of international business, is a fluid-applied roofing system, like the company’s AlphaGuard system products.